Soft Cover Binding

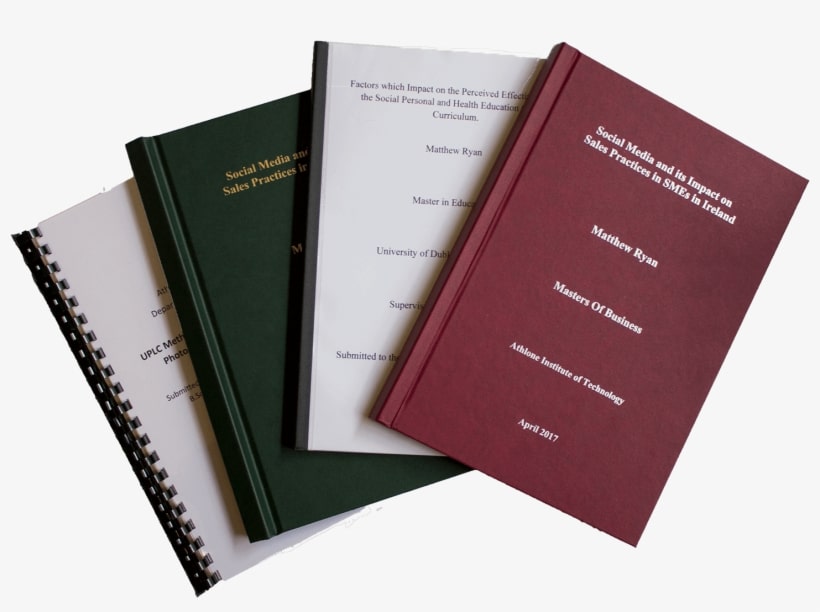

Soft cover binding is one of the most common types of thesis printing and binding. As the name suggests, the cover is soft and flexible and the pages are held in place by a staple or spiral binding. This type of binding is often chosen by students who want a low-cost option that’s easy to use. Soft cover binding is a cost-effective way to bind your thesis. The cover can be printed or unprinted, depending on your preference. You’ll also have a variety of cover colors and textures to choose from. Soft cover bindings are held together with a staple or spiral binding. The binding type will depend on the size of your document and its length. You’ll have a few binding options to choose from, including: – single-stitched binding – double-stitched binding – triple-stitched binding – interlocked binding

Hard Cover Binding

Hard cover binding is another popular option among thesis writers. The hard cover protects the pages and makes your thesis look more professional and sleek. Hard cover binding is also known as case binding, and it comes in two styles: Perfect (or hard) binding and Smyth sewing binding. Hard cover bindings are held together with a comb or sewn binding. The type of binding will depend on the length of your document. You can also choose between a Perfect binding and a Smyth sewing binding. Perfect binding is a simpler, cheaper, and faster option than Smyth sewing binding, which provides a more professional look.

Coil Binding

Coil binding is another popular binding option for thesis printing. With this type of binding, spiral wires are used to secure the pages. Coil binding is ideal when you need a flexible and easy-to-use binding style. It’s also a great option when you want to print your thesis on colored paper. Coil binding is held together with a spiral wire. The type of spiral wire will depend on the size of your document. You can also choose between a single- or double-loop binding. Single-loop binding is a cheaper and simpler option than double-loop binding, which provides a more secure attachment.

Case Binding

Case binding is a popular hard cover binding style that uses a stiff cover and a soft, flexible spine to hold the pages together. This type of binding is often used for larger theses that need a sturdy binding. With case binding, you can also include decorative features, such as gilded edges or a ribbon. Case binding is held together with a soft, flexible spine. You can choose between single- or double-thickness binding. Double-thickness binding provides a sturdier and more durable finish.

Printed on Demand (POD) Binding

This style of binding is ideal for shorter theses that aren’t intended for archival storage. POD binding uses a stiff cover and a soft, flexible spine to hold the pages together. The biggest advantage of POD binding is its low cost. POD binding is less durable than other binding types, but it’s a great option for shorter theses that aren’t meant to be archived. POD binding is held together with a soft, flexible spine. You can choose between single- or double-thickness binding. Double-thickness binding provides a sturdier finish. POD binding is a cost-effective way to bind your thesis. This binding style is ideal for shorter theses that aren’t intended for archival storage. POD binding uses a stiff cover and a soft, flexible spine to hold the pages together. The biggest advantage of POD binding is its low cost. POD binding is less durable than other binding types. It’s a great option for shorter theses that aren’t meant to be archived. POD binding is a cost-effective way to bind your thesis. This binding style is ideal for shorter theses that aren’t intended for archival storage. POD binding uses a stiff cover and a soft, flexible spine to hold the pages together. The biggest advantage of POD binding is its low cost. POD binding is less durable than other binding types. It’s a great option for shorter theses that aren’t meant to be archived. Thesis printing and binding are integral parts of the publishing process. With so many different options available, it can be difficult to choose the best binding type for your needs. By considering certain factors in the production process, however, you can choose the kind of binding that best meets your needs and budget.